Innovative Technologies in Body Armor Testing

Jul 10, 2024

Ensuring the effectiveness and durability of body armor is paramount in personal protection. As threats evolve, so must the technologies used to test and certify body armor systems. This article explores the cutting-edge technologies and methodologies currently shaping the future of body armor testing, ensuring that wearers are provided with the highest level of protection possible.

Advanced Ballistic Testing Methods

Traditional ballistic body armor testing involves firing predetermined rounds at a fixed distance toward a vest mounted on a clay torso. This method, while effective for assessing penetration and blunt trauma, does not account for all real-world variables. Modern testing methods have begun to incorporate a broader range of variables, such as multiple hit scenarios, angle of impact, and the effect of environmental conditions on ballistic performance.

Advanced ballistic gel torso models, which better simulate human muscle tissue and fluid dynamics, are now used to provide more accurate feedback on the non-penetrative trauma (backface deformation) wearers might experience upon being struck by a projectile. High-speed cameras capturing thousands of frames per second are also employed to analyze the interaction between the bullet and the body armor during impact, providing invaluable data for improving armor designs.

3D Body Scanning for Fit Testing

A crucial aspect of effective body armor is its fit and comfort, as improperly fitting armor can compromise protection and mobility. 3D body scanning technology has revolutionized how body armor is fitted to individuals. By creating precise 3D models of an individual’s body, manufacturers can design armor that fits perfectly and accounts for body movement and biomechanics.

This technology allows for customization at an unprecedented scale, catering to diverse body types and operational needs. Improved fit enhances comfort and ensures that the armor provides maximum coverage and optimal ballistic protection where it is most needed.

Use of Artificial Intelligence

Artificial intelligence (AI) plays an increasingly significant role in predicting and enhancing body armor performance under various conditions. Machine learning algorithms can analyze vast amounts of test data to predict how different materials and designs might behave under different ballistic and environmental conditions. This predictive capability enables designers to simulate and iterate armor designs quickly before physical prototypes are ever tested.

AI can also optimize the material composition and layering of body armor, proposing new material hybrids and configurations that might not be intuitive to human designers. This approach not only accelerates the development cycle but also uncovers novel solutions that enhance the effectiveness of body armor.

Environmental and Durability Testing

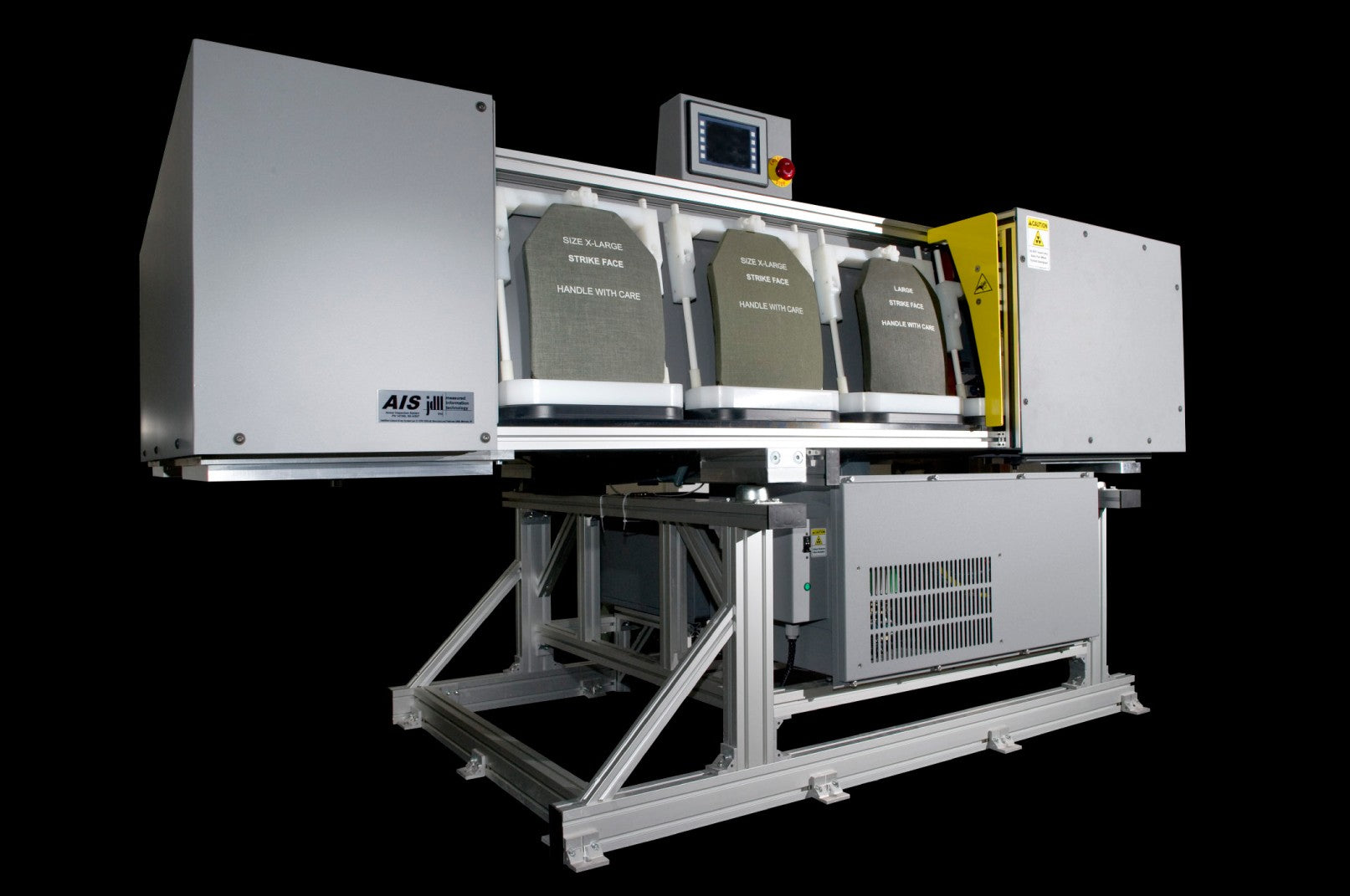

The operational environment plays a significant role in the performance of body armor. Testing now often includes exposing body armor to extreme temperatures, moisture, ultraviolet light, and salt fog to simulate the conditions that armor might face during its service life. These tests ensure that body armor retains its protective properties and structural integrity over time, regardless of the climate or conditions it encounters.

Moreover, the industry has seen the introduction of advanced mechanical testing equipment that can simulate years of wear and tear within days. By accelerating the aging process, manufacturers can predict how long body armor will maintain its protective capabilities over time, guiding warranty periods and replacement cycles.

Virtual Reality and Augmented Reality

Virtual reality (VR) and augmented reality (AR) technologies are being used to simulate wearing body armor in various scenarios, enabling testers to assess the protection, usability, and ergonomics of body armor designs. This technology allows for testing body armor in dynamic situations that would be difficult or dangerous to recreate physically.

The evolution of testing technologies in the body armor industry reflects a broader trend toward more sophisticated, data-driven personal protective equipment development approaches. By incorporating advanced ballistic testing, 3D scanning, AI, environmental testing, and immersive technologies, the industry can ensure that body armor not only meets the current standards but also adapts to the emerging threats and challenges of the future.

Ensuring the effectiveness and durability of body armor through innovative testing saves lives and enhances the operational efficiency of those who put themselves in harm's way to protect others. As technology advances, the potential for further innovation in body armor testing promises even more incredible leaps in safety and performance for all who rely on this critical equipment.

Experience the Future of Protection with Custom Armor Group

At Custom Armor Group (CAG), we’re not just keeping pace with advancements in body armor technology but setting the standard. Our commitment to innovation and safety is reflected in our use of the latest testing technologies, from advanced ballistic testing methods to AI-driven predictive analytics.

Whether you’re in law enforcement, military, or a security-sensitive environment, CAG offers the most reliable, scientifically tested body armor solutions on the market. With our state-of-the-art 3D body scanning and environmental durability tests, we ensure that every piece of armor meets rigorous safety standards and is tailored to fit the unique needs of its wearer.

Please don’t settle for less when it comes to protection. Contact Custom Armor Group today to learn more about our cutting-edge body armor solutions. Visit our website at www.customarmorgroup.com or call us to discuss how we can help you stay safe in the line of duty.

Custom Armor Group — Where Innovation Meets Safety.

← Older Post Newer Post →