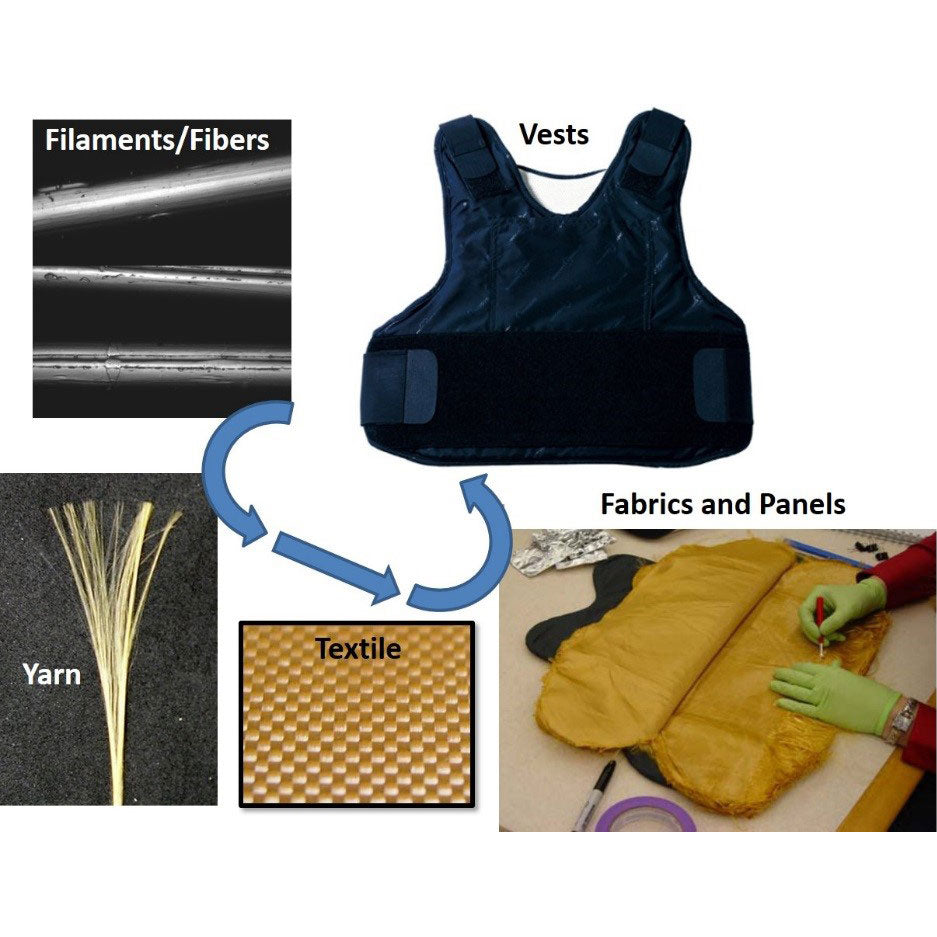

The Core Components Used in Body Armor Production

Jul 24, 2023

Body armor, a staple of safety in various high-risk fields, plays an instrumental role in ensuring the safety and protection of individuals. This includes military personnel, law enforcement officers, fire rescue teams, EMS workers, private security, and civilians. The choice of materials in body armor manufacturing is a complex process dictated by the unique demands of these diverse applications.

This article explores the pivotal raw materials used in modern body armor, evaluating their unique properties, advantages, and potential future developments.

The Role of Body Armor in Different Fields

- Military - For military personnel, body armor must offer robust protection against various threats, including bullets, shrapnel, and explosive blasts. Hard body armor made from materials like ceramics or steel, often layered with UHMWPE or Kevlar, is often used due to its high threat-level resistance.

- Law Enforcement - Law enforcement body armor must balance comfort and mobility with protection. Since law enforcement officers often wear their armor for extended periods, lighter materials like Kevlar and UHMWPE are typically favored.

- Fire Rescue and EMS - While not traditionally associated with body armor, these fields increasingly recognize its benefits. Armor for these professionals must be heat-resistant and comfortable, with flexibility being a key factor. Therefore, hybrid solutions are often used, combining Kevlar with flame-resistant materials.

- Private Security - For private security personnel, the choice of body armor often mirrors that of law enforcement, emphasizing the balance between comfort, mobility, and protection. The security personnel's specific role can also influence the choice of materials.

- Personal Protection for Civilians - Civilians might use body armor for personal protection in various situations. Lightweight, concealable body armor made from materials like UHMWPE and Kevlar is commonly preferred for comfort and discreetness.

History of Body Armor Materials

Body armor, in its most primitive form, dates back to ancient civilizations, where warriors used natural materials to shield themselves from harm. Let's journey through time to understand the evolution of body armor materials.

Ancient and Medieval Era

The earliest body armor was fashioned from leather, bronze, or iron materials, providing protection against primitive weapons like swords, arrows, and spears. Greek hoplites wore bronze cuirasses, while Roman legionaries sported plate armor called lorica segmentation.

Moving into the medieval era, we see the advent of chainmail and plate armor, designed to defend against the ever-improving weapons of war. Chainmail, made from interlinked iron rings, provided a reasonable defense against cutting attacks. In contrast, plate armor, made from large pieces of iron or steel, offered better protection against piercing attacks and blunt force trauma.

Gunpowder Revolution - The introduction of gunpowder weaponry in the 14th century signaled a new era in warfare, rendering traditional plate armor virtually obsolete. Metal cuirasses persisted in some forms, such as the breastplates worn by heavy cavalry, but these were insufficient to defend against firearms.

World War Era to Mid-20th Century - The development of body armor lagged during the early modern period until World War I when the heavy, cumbersome steel helmets and "Brewster Body Shields" were introduced. World War II saw advancements with the flak jackets used by bomber crews. These jackets, made of ballistic nylon, offered some protection against shrapnel but were ineffective against bullets.

Introduction of Kevlar and Modern Materials - The landscape of body armor was forever changed in the 1960s with the invention of Kevlar by chemist Stephanie Kwolek. With its impressive tensile strength, Kevlar was soon incorporated into vests, offering unprecedented protection against bullets and fragments while significantly lighter than its predecessors.

Since then, the development of body armor materials has continued to evolve, introducing more advanced materials such as UHMWPE and different ceramic composites. These materials, often used in conjunction with one another, have provided varying degrees of protection, weight, and flexibility, culminating in the diverse range of body armor we see today.

The journey from leather and bronze to Kevlar and ceramics is a testament to our continuous quest for better protective solutions. As technology continues to advance, we look forward to the future innovations that lie on the horizon.

Critical Materials in Modern Body Armor

- Kevlar: Composition and Role - Kevlar, a para-aramid synthetic fiber, is one of the most recognized materials in body armor. Its high tensile strength-to-weight ratio makes it five times more potent than steel. In body armor, layers of woven Kevlar fabric absorb the energy of a bullet, spreading it across the fabric to mitigate the impact. However, while Kevlar is lightweight and highly effective against specific threats, it can degrade over time and with exposure to moisture.

- Ultra-High-Molecular-Weight Polyethylene (UHMWPE) - UHMWPE is another popular material known for its high strength and lightweight. It functions similarly to Kevlar, absorbing and distributing the energy of a bullet but has a higher cut resistance and is less susceptible to moisture.

- Ceramics: Alumina, Silicon Carbide, Boron Carbide - Ceramic materials provide the advantage of high hardness, effectively disrupting the bullet upon impact. However, ceramic plates are often combined with other materials like Kevlar or UHMWPE, as they can shatter upon bullet impact, limiting their multi-hit capabilities.

- Steel - Steel offers a cost-effective solution for body armor with excellent multi-hit capabilities. However, its weight, compared to other materials, can limit mobility and comfort, making it less ideal for long-term wear.

Factors Influencing the Choice of Materials

Choosing a suitable material for body armor is not to be taken lightly. The decisions made during this process directly impact the wearer's safety, comfort, and overall performance. Several critical factors must be considered to strike the perfect balance.

- Impact Resistance - The most crucial factor is impact resistance, or the ability of the armor to protect against the threats the wearer faces. The material must be able to absorb and disperse the kinetic energy of a bullet or sharp object. More complex materials such as steel and ceramic offer excellent ballistic resistance but can be lighter and more comfortable.

- Weight - The weight of the body armor significantly affects mobility. While often providing robust protection, heavier materials can impede movement and be physically draining over prolonged use. Therefore, materials like Kevlar and UHMWPE, known for their high strength-to-weight ratios, have become increasingly popular.

- Flexibility and Comfort - Flexibility and comfort are paramount for users needing body armor for extended periods. Materials must allow a full range of motion and conform to the body’s contours without causing discomfort. Soft body armor made from flexible materials like Kevlar and UHMWPE often excels in these respects.

- Cost-effectiveness - Body armor needs to be affordable and offer value for money. While materials like Kevlar and ceramics provide excellent protection, they can be costly. More affordable options like steel may be adequate for specific applications, but drawbacks include increased weight.

- Environmental Resilience - The material must be durable and stand up to various environmental conditions. It should not degrade under extreme temperatures, exposure to water, or prolonged UV radiation. Each material has its environmental resilience characteristics, which must be weighed up depending on the conditions the armor will face.

Selecting suitable material for body armor involves a careful evaluation of these factors. Each application might demand a different balance of these factors, underlining the need for various materials to produce body armor. Future advancements in materials science will likely focus on enhancing these attributes even further, offering improved protection, comfort, and longevity.

Innovations and Future Trends in Body Armor Materials

Emerging materials and technologies show promising potential in the body armor industry. Non-Newtonian fluids, which harden upon impact, could offer improved flexibility. Graphene and carbon nanotubes, known for their extreme strength and lightness, might revolutionize the industry.

Advancements in material engineering continue to explore these possibilities, seeking to enhance protection levels, reduce weight, and improve comfort. The future of body armor materials is promising and will likely yield even more sophisticated protective gear.

The journey of raw materials used in body armor has constantly evolved, with each new invention aiming to provide better protection. As we look ahead, emerging materials and engineering practices promise even safer, lighter, and more comfortable body armor for those who put their lives on the line daily.

Where do we go from here?

The landscape of body armor has continuously evolved from the leather and bronze of ancient warriors to the sophisticated blend of Kevlar, ceramics, and UHMWPE used in modern protective gear. These materials have enhanced safety across various fields, from military and law enforcement to fire rescue, EMS, private security, and personal protection for civilians.

The careful selection of these raw materials, balancing impact resistance, weight, flexibility, cost-effectiveness, and environmental resilience, is paramount in body armor manufacturing. It is a testament to the commitment to protecting and protecting those in high-risk fields.

Emerging materials and technological advancements promise exciting new possibilities for body armor. With innovations such as non-Newtonian fluids, graphene, and carbon nanotubes on the horizon, the future of body armor materials promises to deliver even safer, lighter, and more comfortable protection options.

Whether you're a military professional, law enforcement officer, fire rescue worker, EMS worker, private security personnel, or a civilian seeking personal protection, having reliable, effective, and comfortable body armor is crucial. As we continue to push the boundaries of material science, we remain committed to providing high-quality, affordable armor products that meet the unique needs of various end users and deployment operations.

We invite you to contact our team at the Custom Armor Group to learn more about our product offerings. Our team is ready and eager to help you understand the protective solutions best suited to your needs. Trust in the strength and reliability of our products because at the Custom Armor Group, your safety is our highest priority.

References

- US Department of Justice (2020). "Selection and Application Guide to Ballistic-Resistant Body Armor for Law Enforcement, Corrections, and Public Safety".

https://www.ncjrs.gov/pdffiles1/nij/247281.pdf

- Dupont (2021). "Kevlar® for Military Body Armor".

https://www.dupont.com/products/kevlar-military-body-armor.html

- Future Fibres (2019). "Ballistic Materials".

https://www.futurefibres.com/ballistic-materials/

- Nguyen, Q. (2015). "Body Armor Materials & Technologies".

https://www.azom.com/article.aspx?ArticleID=11738

- Honeywell (2021). "Spectra®: Advanced Materials for Ballistic Protection".

https://www.honeywell-spectra.com/applications/ballistic-protection/

- Mayfield, R. (2019). "The Evolution of the Flak Jacket".

https://www.wearethemighty.com/mighty-tactical/history-flak-jacket/

- Bashir, A., Mokhena, T. C., Sefadi, J. S., Almehmadi, M., Ali, F., Alharbi, H., & Kim, H. C. (2020). "A Review on the Ballistic Impact Behaviors of Fiber Reinforced Composites".

https://www.mdpi.com/1996-1944/13/14/3081

- Saeed, K., Farooq, U., & Ahmad, F. (2017). "Military Textiles: An Overview".

https://www.researchgate.net/publication/316640314_Military_Textiles_An_Overview

- Campbell, F.C. (2012). "Structural Composite Materials".

https://www.asminternational.org/documents/10192/1849770/05287G_Chapter_1.pdf/

- Zweben, C. (2019). "Advanced Composite Materials for Ballistic Protection".

https://www.sciencedirect.com/science/article/pii/B9780081006740000035

Note: Access to some of these sources might be restricted due to paywalls or subscription requirements. The availability of URLs and the information they contain can also change over time.

← Older Post Newer Post →